Principle

The torque generated by engine is transferred to blade shaft through the pulley. The blade shaft in high speed rotation drives the diamond blade in high rotation to cut the road.

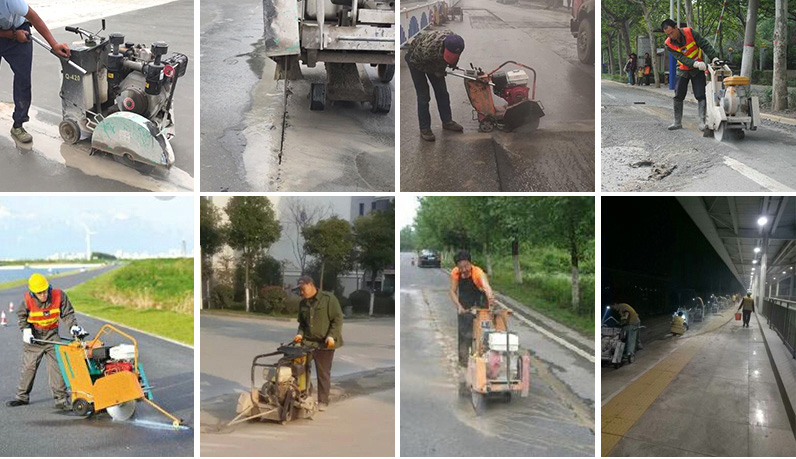

Application

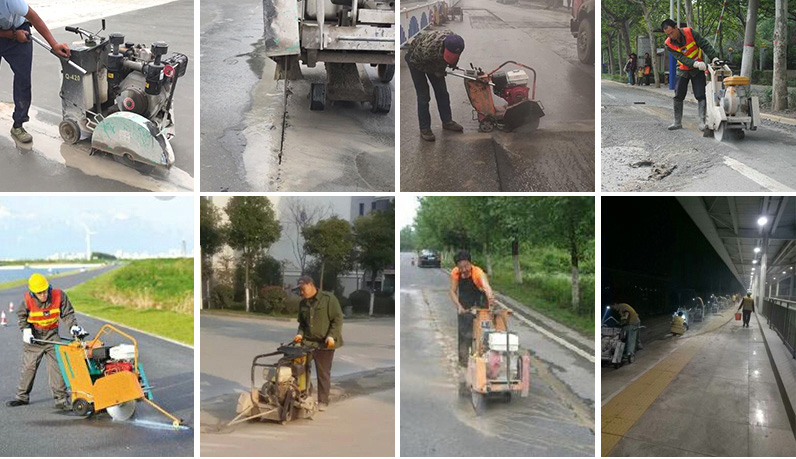

Floor saws can be widely used in service work, road maintenance, relief effort etc.

Floor saws are designed to cut both concrete (green or cured, with or without rebar) or asphalt.

Floor saws are suitable to cut floors, pavement, walkways, trenches to lay pipe, channels for laying cable, ramps and other flat sawing applications.

Globalokgoods has many models to choose: for horse power, from 5.0HP to 14HP; for blade, from 300mm to 500mm. Welcome to choose according to your demand. Choosing the right machines can increase productivity and improve construction quality.

Reliability

The guide-bar with anti curl and anti vibration function, to ensure straight cutting, extend blade and machine usage life..

Build-in wheels make it easy to cut beside the wall.

Bearing of screw stem is in stainless steel material for long service life.

Easy-remove, rustless poly water tank provides an optimum flow and volume of water to both sides of the blade, reduce blade temperature and restrain dust when cutting.

Small volume is easy to transport and store.

Adjustable cutting depth

The crank can adjust cutting depth easily.

Elevating device is manual locked, which ensures the same cutting depth.

Easy operation

Humanized design handle with easy and comfortable operation.

Hinged front,lift-up blade guard is designed to provide easy blade replacement and inspection.

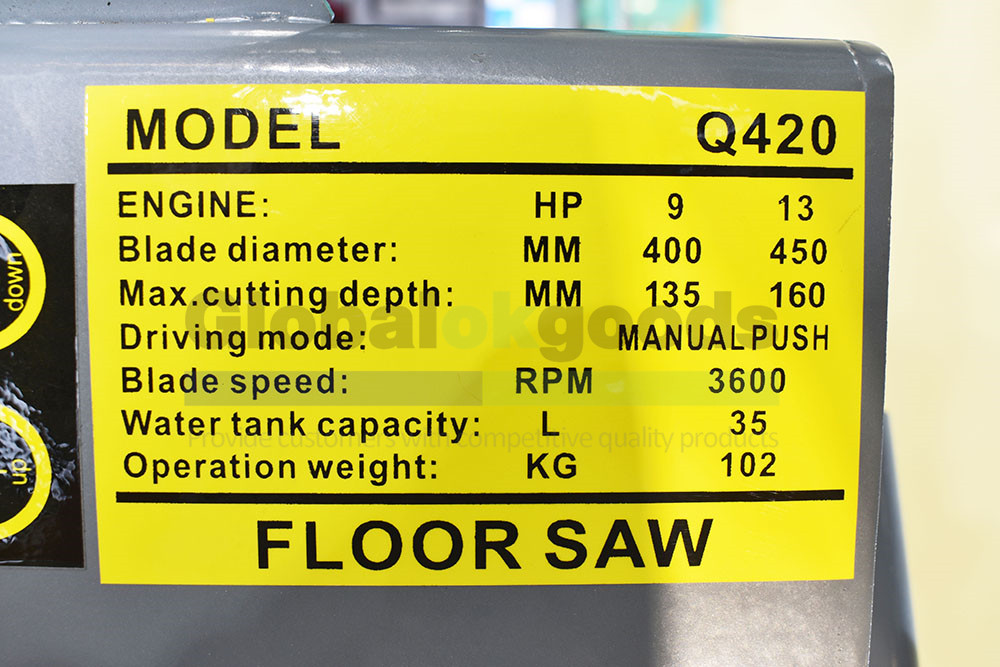

Technical Data

The torque generated by engine is transferred to blade shaft through the pulley. The blade shaft in high speed rotation drives the diamond blade in high rotation to cut the road.

Application

Floor saws can be widely used in service work, road maintenance, relief effort etc.

Floor saws are designed to cut both concrete (green or cured, with or without rebar) or asphalt.

Floor saws are suitable to cut floors, pavement, walkways, trenches to lay pipe, channels for laying cable, ramps and other flat sawing applications.

Globalokgoods has many models to choose: for horse power, from 5.0HP to 14HP; for blade, from 300mm to 500mm. Welcome to choose according to your demand. Choosing the right machines can increase productivity and improve construction quality.

Reliability

The guide-bar with anti curl and anti vibration function, to ensure straight cutting, extend blade and machine usage life..

Build-in wheels make it easy to cut beside the wall.

Bearing of screw stem is in stainless steel material for long service life.

Easy-remove, rustless poly water tank provides an optimum flow and volume of water to both sides of the blade, reduce blade temperature and restrain dust when cutting.

Small volume is easy to transport and store.

Adjustable cutting depth

The crank can adjust cutting depth easily.

Elevating device is manual locked, which ensures the same cutting depth.

Easy operation

Humanized design handle with easy and comfortable operation.

Hinged front,lift-up blade guard is designed to provide easy blade replacement and inspection.

Technical Data

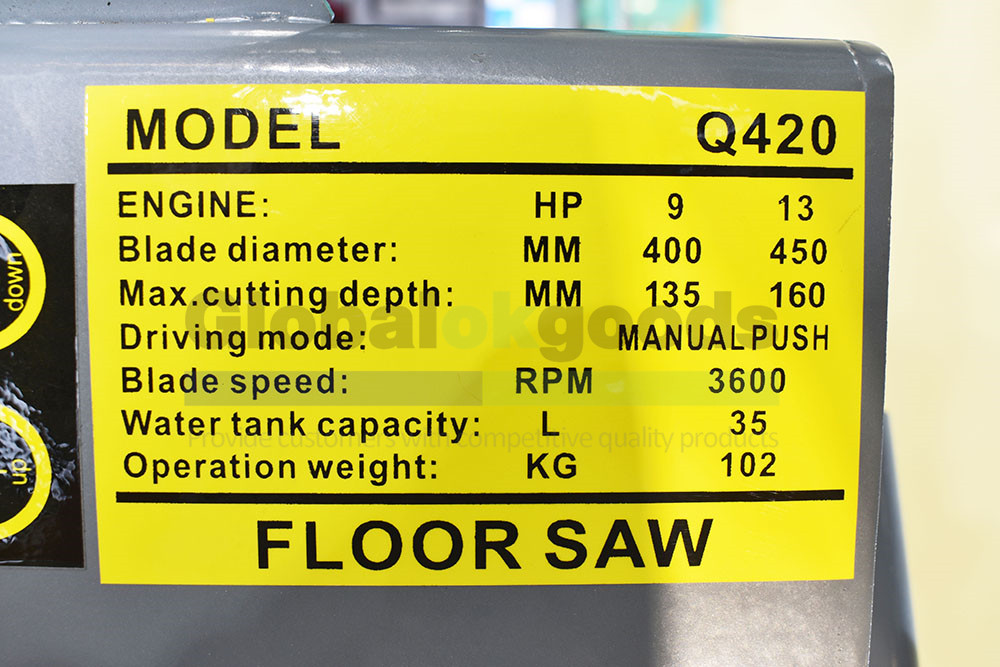

| Model | WH-Q420H | WH-Q420L | WH-Q420S | WH-Q420D |

| Engine type | Air-cooled single cylinder 4-stroke | |||

| Engine | Honda GX390 | Loncin G420F | B&S25T2 | Diesel,WH186F/ 188F |

| power(HP) | 13.0 | 14.0 | 13.5 | 9 |

| Operating Weight(kg) | 102 | 137 | ||

| Shipping Weight(kg) | 110 | 145 | ||

| Max,cutting depth(cm) | 16 | |||

| Driving mode | Manual push | |||

|

Water tank capacity(L) |

35 | |||

| Blade Size(cm) | 40.0-50.0 | |||

| Package size(L*W*H)(cm) | 96*58*90 | |||

| Engine Periodic Maintenance Schedule | ||||||

| Performed at every indicated month or operation hours interval, whichever comes first. | REGULAR SERVICE PERIOD | |||||

| Item | Directive | Each use | First month or 20 Hrs. | Every 3 months or 50 Hrs. | Every 6 months or 100 Hrs. | Every year or 300 Hrs. |

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √* | |||||

| Sediment cup | Clean | √ | ||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel rank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

| * Replace the paper element type only. | ||||||

| (1) Service more frequently when used in dusty areas. | ||||||

| (2) These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures. | ||||||

| Floor saw Periodic Maintenance Schedule | ||||||

| Directive | Daily before starting | After first 5 Hrs. | After first 50 Hrs. | Every week or 25 Hrs. | Every month or 100 Hrs. | Every 3 months or 300 Hrs. |

| Check fuel level | √ | |||||

| Check oil level of machine | √ | |||||

| Check fuel level line and fittings for cracks or leaks | √ | |||||

| Check and tighten engine clylinder screws | √ | √ | ||||

| Check and tighten external hardware | √ | √ | ||||

| Check V-belt | √ | |||||

| Clean engine cooling fins | √ | |||||

| Clean recoil starter | √ | |||||

| Clean engine muffler and exhaust port | √ | |||||

| Note: If engine performance is poor, please check, clean and replace air filter elements as needed. | ||||||

USD

USD EUR

EUR GBP

GBP CNY

CNY