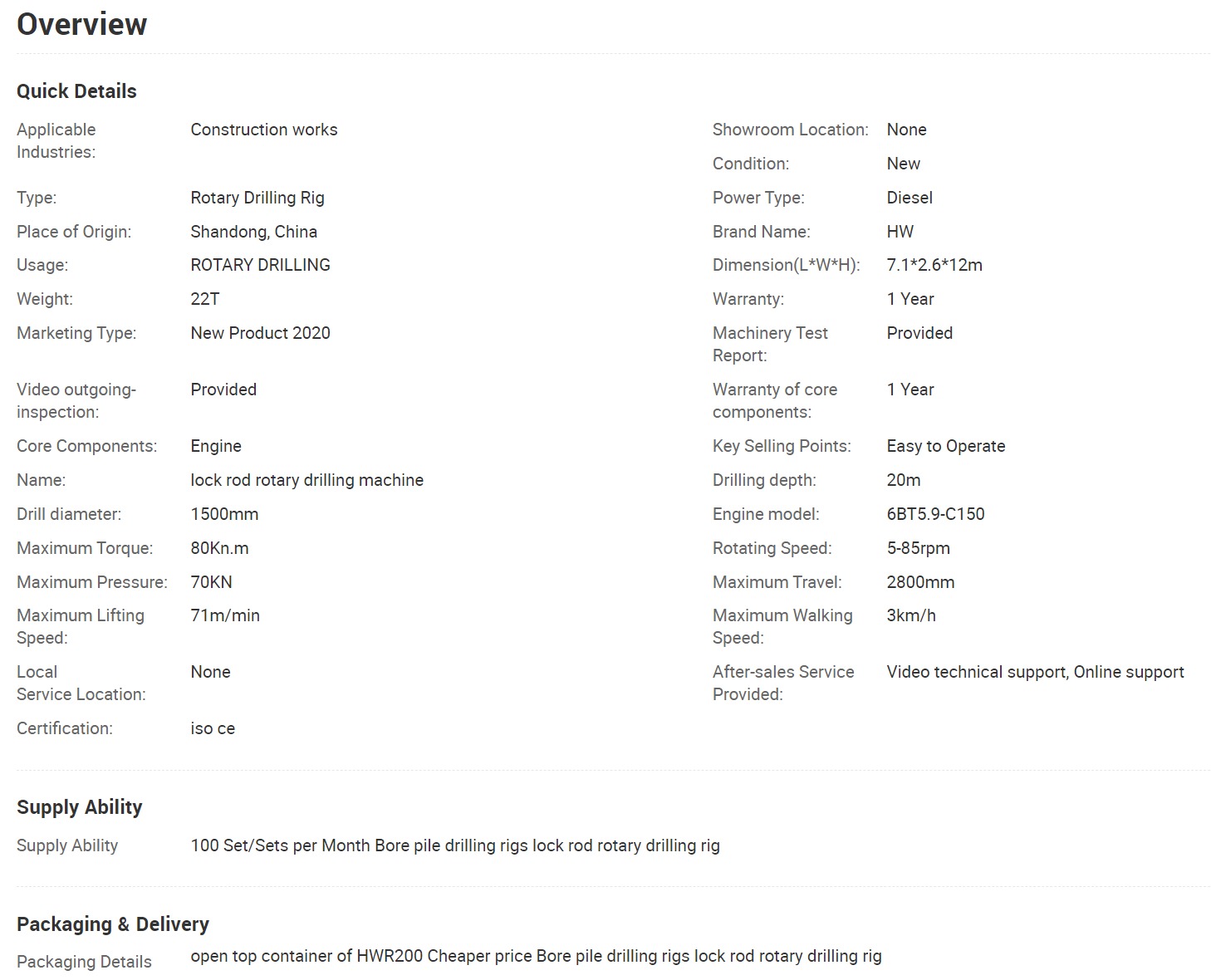

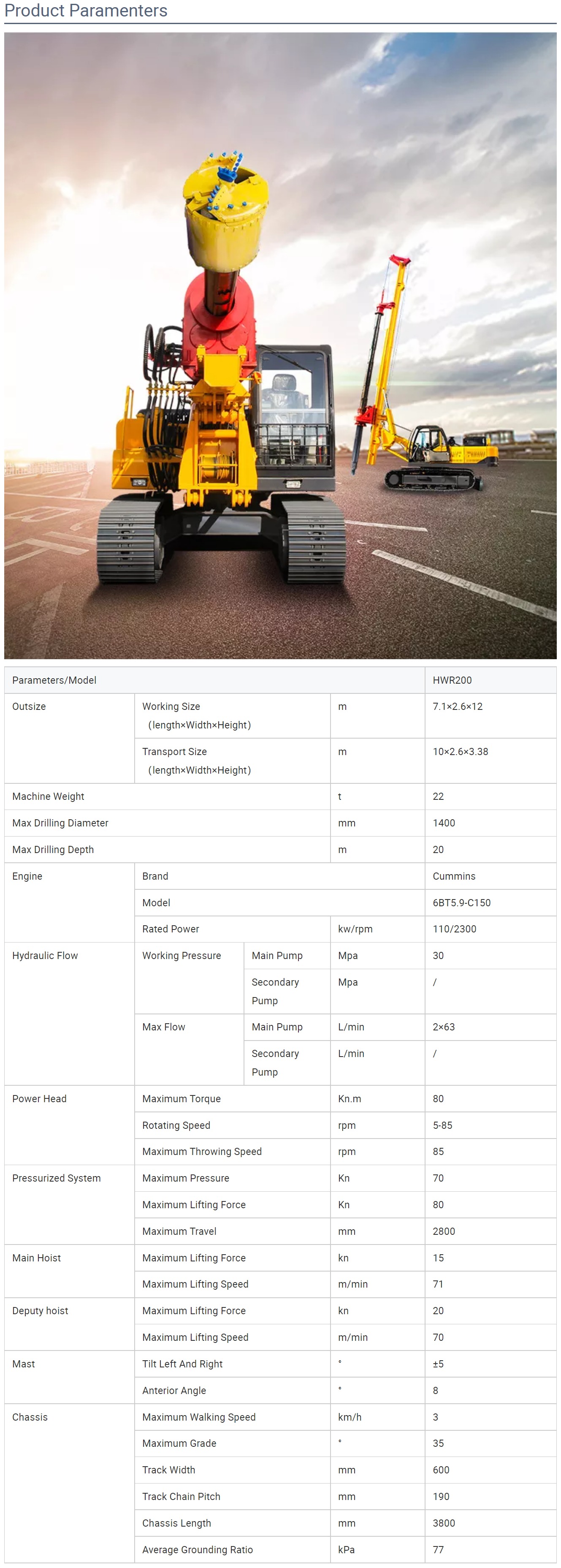

Lock rod rotary drilling machine

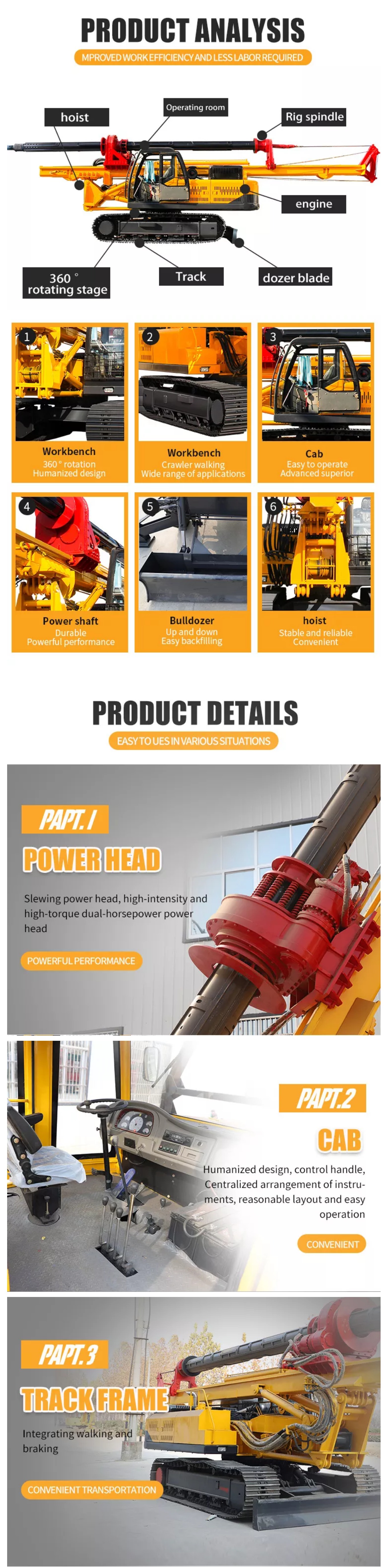

Lock rod rotary drilling machineLock rod rotary drilling machine introduces the back-inclination large triangle structure with stationary luffing support, which is suitable for working conditions of low-tonnage drilling rig, improving the rigidity of working mechanism and enhancing the stability of whole drilling rig while achieving easy transportation;

The imported Cummins engine can minimize fuel consumption with the help of two optional accelerator control modes;

The main winch is designed with a high displacement motor, achieving more sensitive response and more reliable working and also getting rid of the difficulty in earth dumping for pile holes of small diameter;

The feature for lock rod rotary drilling machine:

1.The standard reducer joint can adjust drill rod combination according to actual conditions, thus effectively reducing fuel

consumption and improving construction efficiency;

2.It introduces the proprietary intelligent control system, CAN bus and PLC, including automatic/manual adjustment of drilling mast verticality, depth automatic detection and display, intelligent fault diagnosis and control.

USD

USD EUR

EUR GBP

GBP CNY

CNY