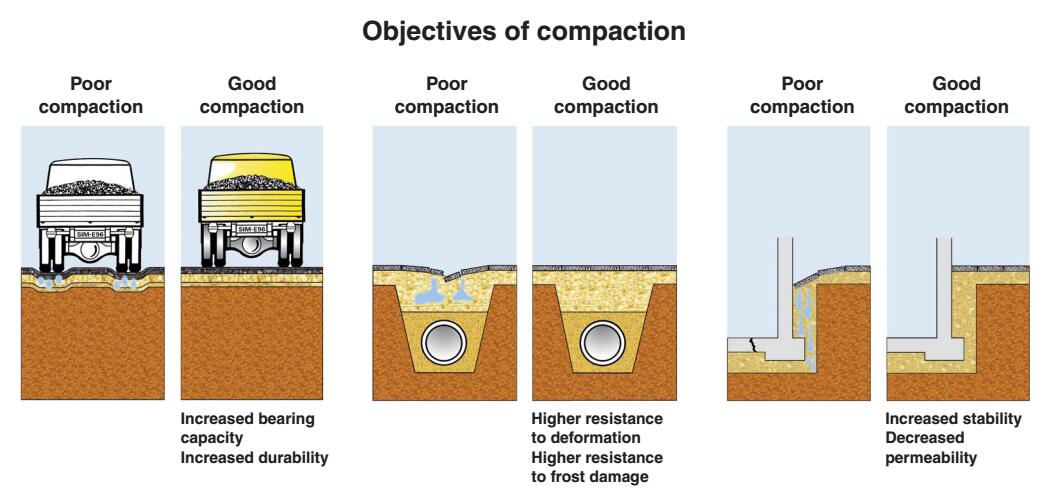

Principle:

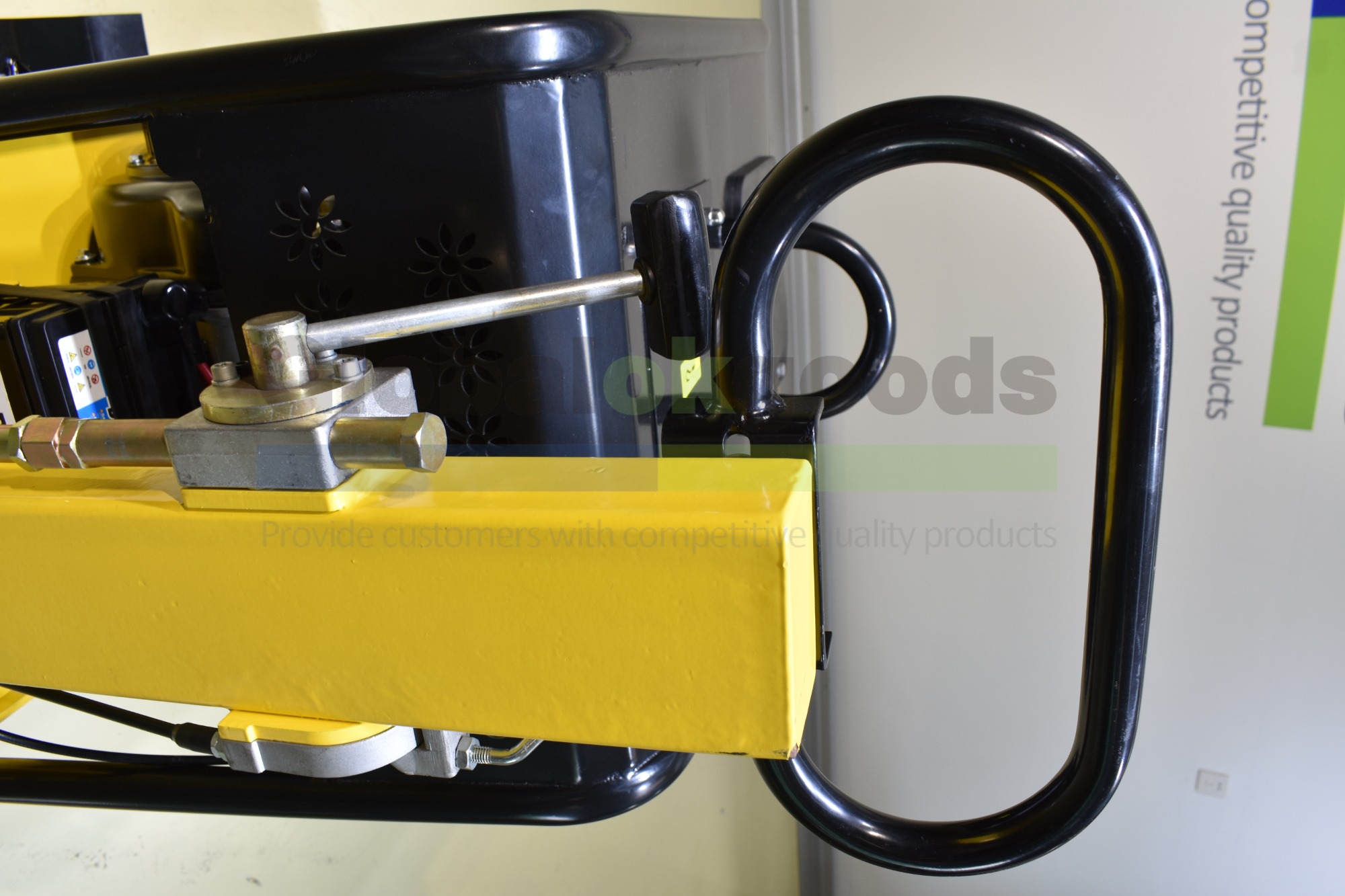

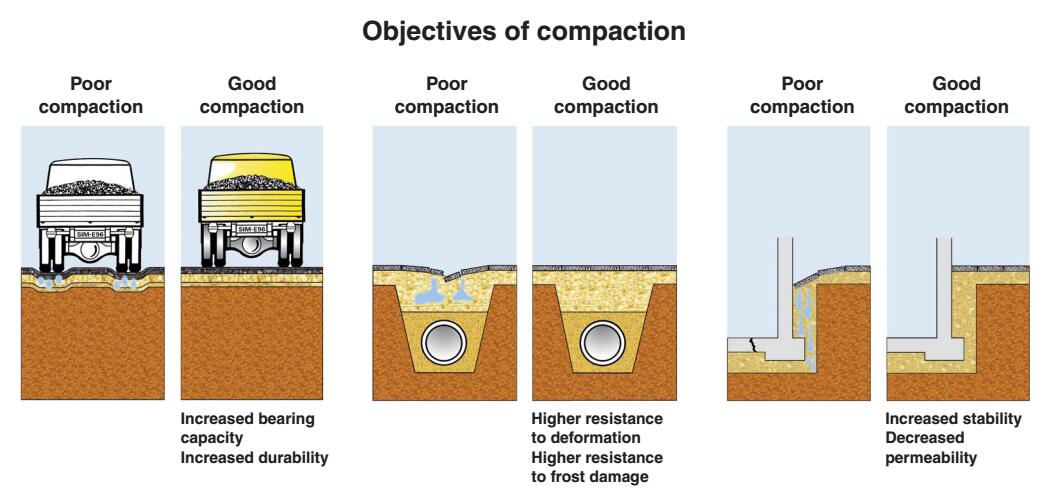

Plate compactors are the machine that compact the ground and they intend to make the surface smooth by transmitting vibration through vibrating plate, whose power generated from the motor in vibrator case. The exciter system(directed vibrator) is driven via V-belt and centrifugal clutch.

Application:

Plate compactor is an indispensable piece of construction equipment. As the professional manufacturer of this item, Globalokgoods has many models of plate compactors for different construction jobs, which differ in size, weight, power and operating mechanism.

Globalokgoods plate compactors are designed to be used for trench compaction, earthworks, road maintenance, landscaping, brick paving(with rubber mat), driveway topping etc.

Globalokgoods plate compactors can compress different types of soil(excluding soil with much water, especially clay soil), asphalt and gravel.

Welcom to choose according to your demand. Choosing the right machines can increase productivity and improve construction quality.

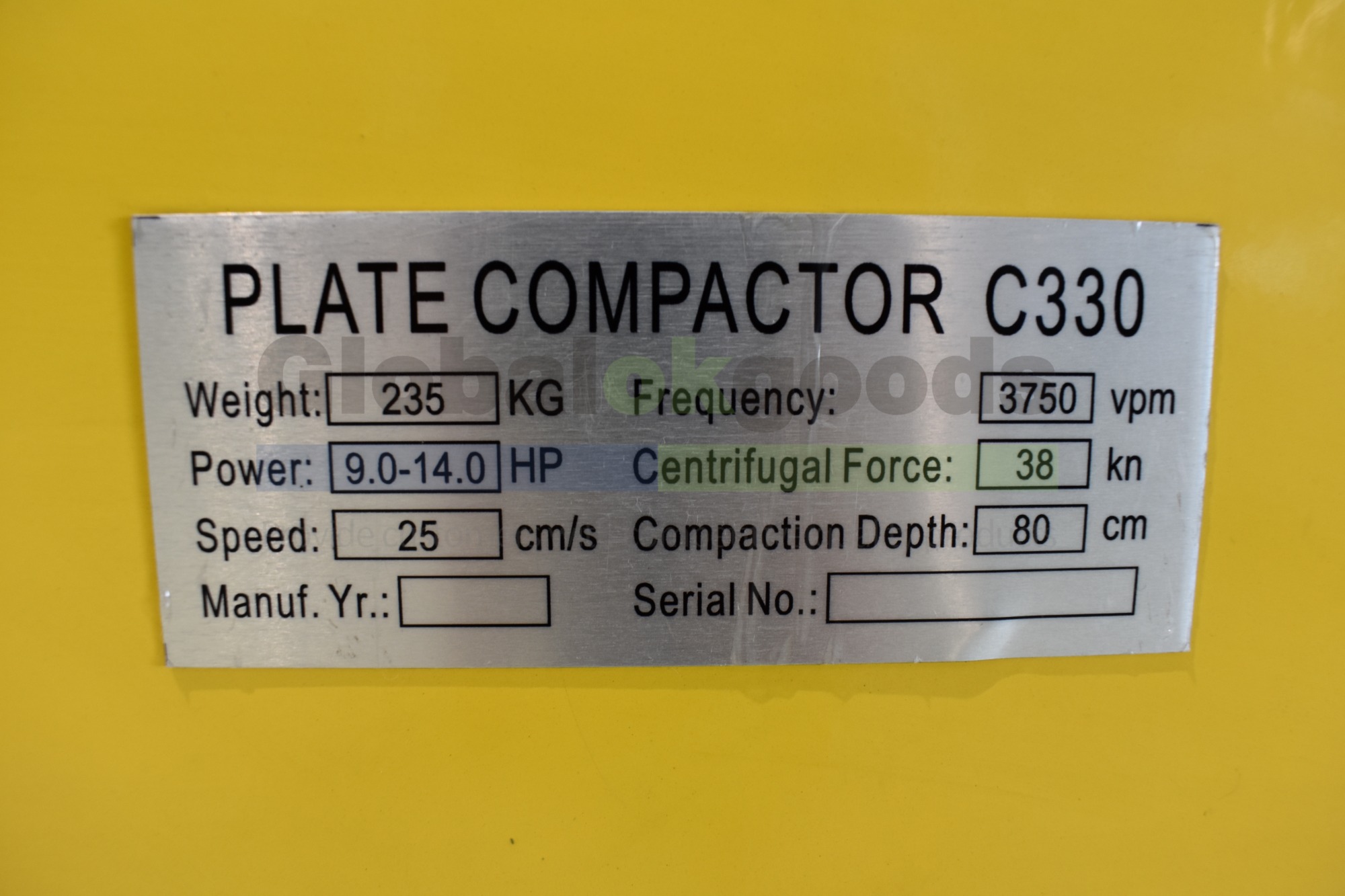

Technical Data

Plate compactors are the machine that compact the ground and they intend to make the surface smooth by transmitting vibration through vibrating plate, whose power generated from the motor in vibrator case. The exciter system(directed vibrator) is driven via V-belt and centrifugal clutch.

Application:

Plate compactor is an indispensable piece of construction equipment. As the professional manufacturer of this item, Globalokgoods has many models of plate compactors for different construction jobs, which differ in size, weight, power and operating mechanism.

Globalokgoods plate compactors are designed to be used for trench compaction, earthworks, road maintenance, landscaping, brick paving(with rubber mat), driveway topping etc.

Globalokgoods plate compactors can compress different types of soil(excluding soil with much water, especially clay soil), asphalt and gravel.

Welcom to choose according to your demand. Choosing the right machines can increase productivity and improve construction quality.

Technical Data

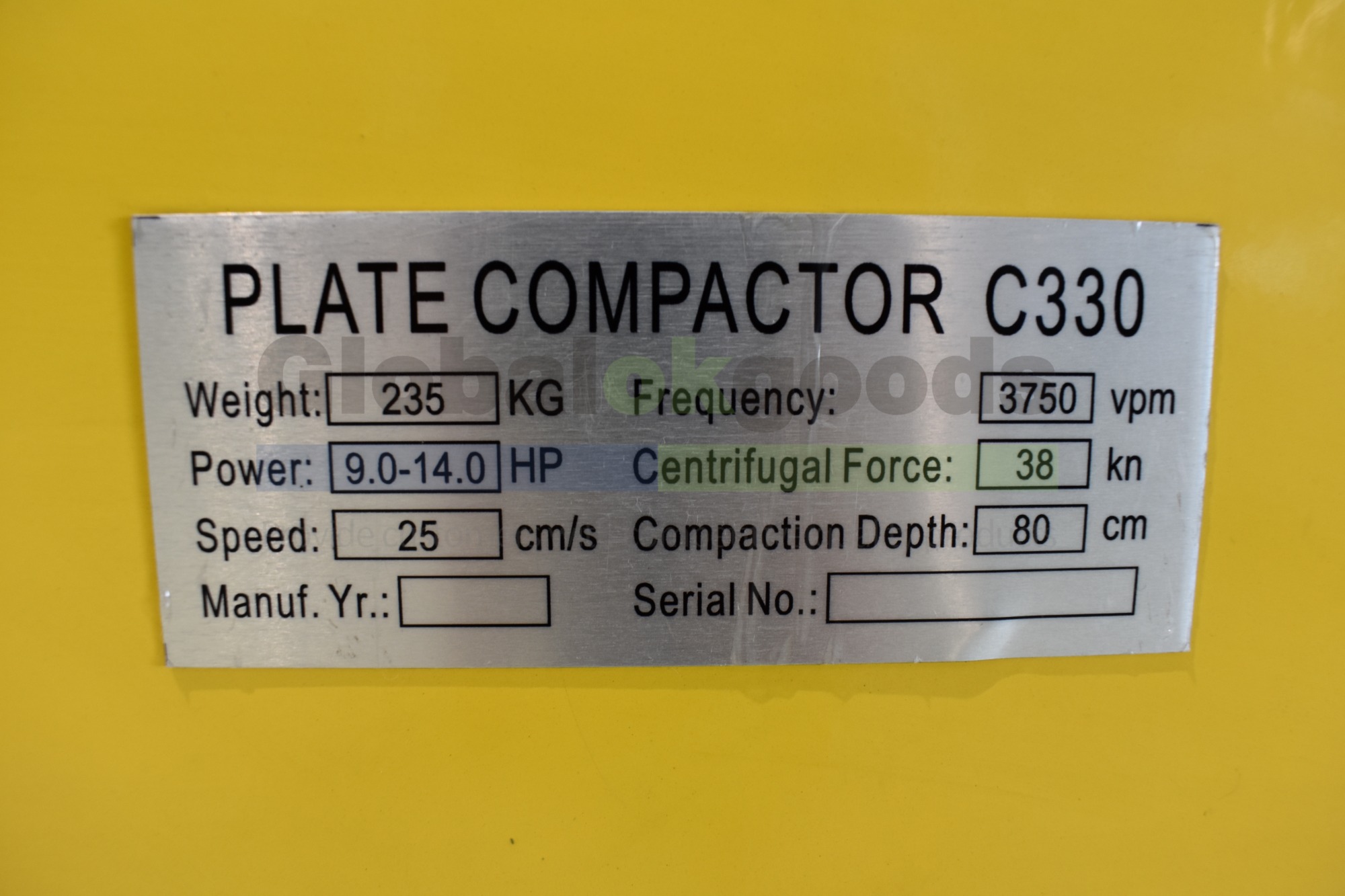

| Model | WH-C330H | WH-C330L | WH-C330D | WH-C330S |

| Engine type | Air-cooling,single cylinder,4-stroke | |||

| Engine | Honda GX390 |

Loncin G420F |

Diesel WH186F/188F | B&d25T2 |

| Power(HP) | 13.0 | 14.0 | 9.0 | 13.5 |

| Operating Weight kg | 232 | 232 | 256 | 232 |

| Shipping Weight kg | 248 | 248 | 272 | 248 |

| Size of base plate(L*W)(cm) | 83.5*67 | |||

| Compaction depth(cm) | 80 | |||

| Max.centrifugal force(KN) | 38 | |||

| Vibration frequency(V.P.M) | 3750 | |||

| Travel speed(cm/s) | 25 | |||

| Package size(L*W*H)(cm) | 96.5*55.5*109 | |||

| Engine Periodic Maintenance Schedule | ||||||

| Performed at every indicated month or operation hours interval, whichever comes first. | REGULAR SERVICE PERIOD | |||||

| Item | Directive | Each use | First month or 20 Hrs. | Every 3 months or 50 Hrs. | Every 6 months or 100 Hrs. | Every year or 300 Hrs. |

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √* | |||||

| Sediment cup | Clean | √ | ||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel rank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

| * Replace the paper element type only. | ||||||

| (1) Service more frequently when used in dusty areas. | ||||||

| (2) These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures. | ||||||

| Engine Periodic Maintenance Schedule | ||||||

| Performed at every indicated month or operation hours interval, whichever comes first. | REGULAR SERVICE PERIOD | |||||

| Item | Directive | Each use | First month or 20 Hrs. | Every 3 months or 50 Hrs. | Every 6 months or 100 Hrs. | Every year or 300 Hrs. |

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √* | |||||

| Sediment cup | Clean | √ | ||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel rank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

| * Replace the paper element type only. | ||||||

| (1) Service more frequently when used in dusty areas. | ||||||

| (2) These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures. | ||||||

| Plate compactor Periodic Maintenance Schedule | ||||||

| Directive | Daily before starting | After first 5 Hrs. | After first 50 Hrs. | Every week or 25 Hrs. | Every month or 100 Hrs. | Every 3 months or 300 Hrs. |

| Check fuel level | √ | |||||

| Check oil level of machine | √ | |||||

| Check fuel level line and fittings for cracks or leaks | √ | |||||

| Tighten bottom plate hardware | √ | √ | ||||

| Check and tighten engine clylinder screws | √ | √ | ||||

| Check and tighten external hardware | √ | √ | ||||

| Check V-belt | √ | |||||

| Clean engine cooling fins | √ | |||||

| Clean recoil starter | √ | |||||

| Change vibrator oil | √ | √ | ||||

| Clean engine muffler and exhaust port | √ | |||||

| Note: If engine performance is poor, please check, clean and replace air filter elements as needed. | ||||||

USD

USD EUR

EUR GBP

GBP CNY

CNY